|

Installing

a Lev-L-Ine Machinery Mount |

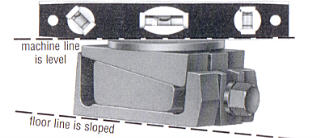

- Make sure

floor is clean and free of all obstructions and loose or broken

concrete.

- Place mounts

under the machine, ensuring that the spherical bearing seats are

centered beneath the mounting points. If anchor bolts are being

used, place mounts over the anchor so adjusting bolts are accessible.

- Adjust the

mounts to their lowest positions, then adjust the mount up by

turning the bolts two turns or until all surfaces are bearing

and the maximum amount of travel is available. ( Note that the

LL-7 leveling bolt has left hand threads).

- Carefully

lower machine onto the mounts. If necessary, raise the mounts

until all spherical bearing seats contact the mounting points.

- Check the

level on the machine to find the highest mounting point.

- Gradually

bring the rest of the machine up to the same level as the machine

high spot by turning the adjusting bolts. Never make too large

a vertical lift using any one mount. This could cause a uneven

weight distribution on the mounts and possible contribute to component

failure. If the load on the mount is in excess of one half its

rated load, it is recommended that a mechanical or hydraulic lifting

device be used to raise the machine in order to adjusting bolt.

When maximum vertical adjustment has been reached, a noticeable

increase in torque will be noticed. Further adjustment could cause

component failure.

- If the anchor

bolts are used, tighten all anchor bolts to allowable torque limits

after leveling (per manufacturer specifications). Recheck level.

- It is important

to note that the mounts are designed to lift only. It is not necessary

to lower the mount with a load applied, a hydraulic or other mechanical

lifting device should be employed to relieve the load from the

mount, then the mount may be adjusted down to the desired level.

|

Click

here for Unisorb LL Technical Data Sheet - PDF Format Click

here for Unisorb LL Technical Data Sheet - PDF Format

|

|

|

WILREP LTD.

email: info@wilrep.com

Tel: (905)625-8944 Fax:(905)625-7142

Toll Free: 1-888-625-8944

|